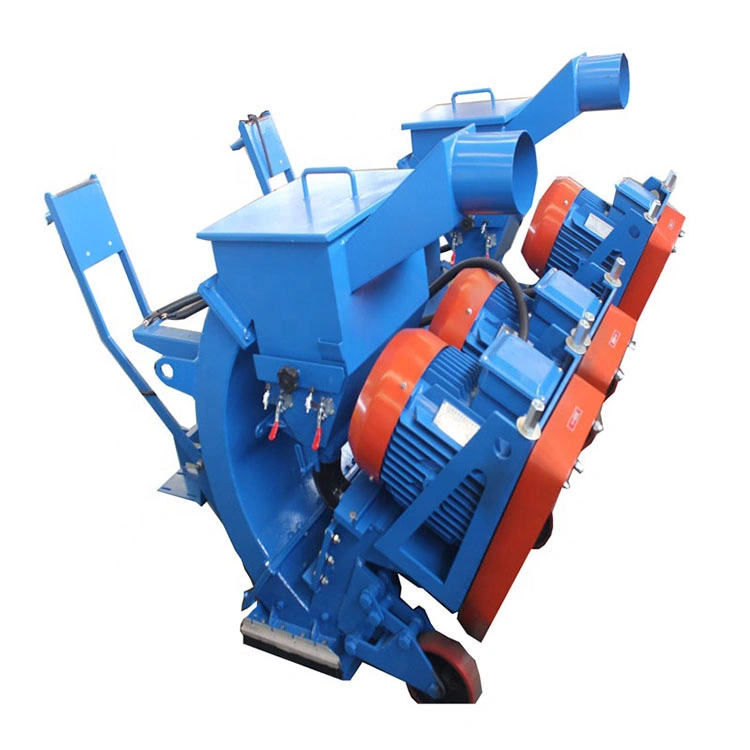

Road Shot Blasting Machine on Concrete Floor for Epoxy Coating Cleaning

Mobile Road Concrete Surface Shot Blast Cleaning Machine 1. Functions outlinedPHLM mobile concrete surface shot blasting

Description

Basic Info.

| Model NO. | phlm |

| Automation | Automatic |

| Certification | CE |

| Feature | Rust / Corrosion Proof |

| Condition | New |

| Customized | Customized |

| Effective Cleaning Width | 240mm, 550mm, 600mm and 800mm |

| Loading | Container |

| After-Sales Service Provided | Engineers Available to Service Machinery Overseas |

| Mobile Shot Blasting Machine Warranty | One Year |

| Abrasive | Steel Shot, Steel Grit, etc |

| Exporting Experience | Since 2009 |

| Industrial Experience | Over 20 Years |

| Composition | Shot Blasting Machine and Dust Collector |

| Wear Parts Material | High Chrome Castings |

| Transport Package | Wooden Case, Pallet, or Customized |

| Specification | CE |

| Trademark | Puhua |

| Origin | Shandong China(Mainland) |

| HS Code | 8424300000 |

| Production Capacity | 200 Sets Per Year |

Product Description

Mobile Road Concrete Surface Shot Blast Cleaning Machine

1. Functions outlinedPHLM mobile concrete surface shot blasting machine adopts this way to get blasting by medium (Steel shot or steel grit) to a very high speed and a certain angle to the workpiece surface, this shot blasting medium can clear the workpieces' surface, and then inside the machine the medium and impurities will be recovered respectively through the vacuum cleaner air and can be reused again.Our equipment construction is simple and convenient operation, do not need to closed road for construction, the construction cost is low, the equipment has high mobility. The machine is equipped with dust-removal unit, in the process of the construction, it can be done no dust and soilless, no pollution, and the medium can be recycled. 2. The concrete surface shot blasting machine application Along with the shot blasting processing equipment continuous improvement and mature technology, blasting process and equipment have entered the developed country for their highway maintenance, bridge construction and airport maintenance, etc. 2.1 Concrete bridge surface treatment Concrete bridge deck pavement is widely used in waterproof layer, greatly reducing the concrete bridge caused damage for water penetration, prolong the service life of the bridge. But with the increase of the traffic flow, and at the same time appeared waterproof layer and bridge deck bonding strength shortage and produce the damage. The concrete bridge also often happen damage, as well as water penetration and even cause concrete loose, fall off, the corrosion of reinforcement. Because the concrete surface layer blasting treatment failed to completely remove surface residue, which caused the reasons of the above diseases, no reserve some rough surface to ensure that the waterproof layer and compressive strength of the bottom floor.Through the blast cleaning to clean up concrete surface laitance and impurity, at the same time roughening process for the concrete surface, make its surface form uniformity rough surface, greatly improving the waterproof layer and compressive strength of concrete base, can fully exposed concrete crack damage and can take remedial measures in advance.2.2 Steel bridge surface cleaning, anticorrosive coating pretreatment In the bridge anticorrosion fields, shot blasting equipment have a wide range of applications, especially in the steel corrosion, shot blasting machine has become an indispensable construction equipment.In most of the Bridges which have been built, before the anti-corrosion primer or other spraying , all choose to use blasting technology for surface cleaning and roughness processing.Using shotblast processing steel bridge deck can achieve SA2.5 / SA3 steel cleanliness requirements, and can control the roughness degree to meet the coating requirements. The whole process is no dust operation, convenient to move, construction efficiency is high.2.3 Shot blasting equipment clean-up the tunnel concrete pavement2.4 Asphalt road surface sliding treatment2.5 Rubber deposit removal in the airport or other concrete / steel plate3. Composition of equipmentThis equipment is mainly composed of blasters, recovery unit, running mechanism, separator, dust removal system, shot control system, electric control system, etc. Clean up the road, through the control and choice shot particle size, shape, as well as adjustment and set the machine speed of running, control shot blasting flow, get different shot blasting strength, get different surface treatment effect. Shot blasting machine according to the running way, it can be divided into three kinds: hand push type, vehicular and its self-propelled. 4. Dust removal system With a better understanding of environmental awareness, protection, management, improving the environment has been the consensus of the whole society. With our long-term research, analysis, practice get shot blast machine industry experience, our factory make the new design with every shot blasting machine, we aims to improve our working conditions for employees, improve the comprehensive economic benefits. Dust removal system including dust collector, fan, fan piping, the connection pipeline between filter and the main machine, etc. PH854 filter is designed for concrete shot blasting machine matching design blowback type dust removal equipment, also can be used in pavement strong strength cleaning equipment matching dust. The machine volume is small, convenient to move, convenient operation, it is the preferred products to clean road surface.

The vacuum cleaner through the three way blowback soot, using pulse valve, the use of sequence control principle, to ensure that vacuum cleaner circulation loop clear; Use the original fat gather dust hose, ensure connection wear-resisting, reliable; Use of imported filter paper, ensure dust removal effect; Make vacuum cleaner can safe, stable long-term work. Fan drive bearing imported high-speed bearing, ensure the stable and reliable transmission.

1 | Shot blasting turbine | Quantity | 2 units |

| Blade structure | Straight line | ||

| Blasting capacity | 180 kg/min | ||

| Power | Power: 2*11 kw | ||

| Speed | Speed: 76 m/s | ||

| 2 | Shot blasting system | Blasting capacity | Concrete surface effect rate: 320 m2/h |

| Cleaned the maximum size | 550 mm | ||

3 | Separator | Separating capacity | 30 T/H |

| Wind speed of separator | 6-8 m/s | ||

| Waste content of separator | ≤1% | ||

| Quantity | 1 set | ||

4 | Driving system | Motor power | 0.75 kw |

| Unload driving speed | 5-25 m/min (frequency control) | ||

| Shot blasting speed | 0.5-5 m/min (frequency control) | ||

5 | Medium | First loading | 160 kgs |

| Abrasive | Steel shot or steel grit | ||

| Diameter suggestion | 1.2-2.0 mm | ||

6 | Dust collector | Filtering material | Polyester coated fitter cartridge |

| Quantity | 1 set | ||

| Total power | 7 kw | ||

| Filter cartridge | 8*φ200*400 mm | ||

| Air flow | 1250 m3/h | ||

| Pipe diameter | Φ150 mm | ||

| Overall dimensions | L2050* W1050* H1530 mm | ||

| Weight | 620 kgs | ||

| 7 | Shot blasting machine | Overall dimensions | L1900* W930* H1200 mm |

| Weight | 880 kgs | ||

| 8 | Noise | ≤95 dB | |

| 9 | Total power | About 29.75 kw | |

Advantage:

| 1 | 20 years professional production experience in shot blasting machinery industry. |

| 2 | 22,000 m^2 production workshop, strong production capacity. |

| 3 | Professional senior engineer develop the best solution. |

| 4 | Strict quality control system, CE, BV, ISO9001 certificate available. |

| 5 | Main components adopt imported international famous brand. |

| 6 | Timely delivery, one hour to Qingdao port. |

| 7 | Professional after-sale service, Email will be reply in 24 hours. |

| 8 | Site installation and commissioning in your factory. |

Notice:

According to your requirements, the most suitable machines will be designed for your workpieces, please indicate the following details.1. What kind of workpiece will you clean?2. The workpiece size, length, width, height and weight of maximum workpiece.3. How many workpieces do you want to clean per day?Based on this detail information, the detailed technical proposals will be sent to you for reference.Trade Information:MOQ: 1set.Settlement Currency: USD, RMB, EUR.Trade mode: FOB (FCA), CIP, CFR, CIF, DDU, DDP, Turnkey.Payment term: 30% deposit by T/T, the balance paid before delivery or L/C at sight.Delivery time: Within 5-15 days according to different type equipment.

Welcome to visit our company in Qingdao.

Our Contact

Send now