Taa Brand Rotary Drum Type Shot Blasting Cleaning Machine Wheel Blast Machine

Description

Basic Info.

| Model NO. | Drum Type Shot Blast Machine-TS |

| Automation | Automatic |

| Certification | RoHS, ISO |

| Feature | Critical Cleaning / Residue Free |

| Condition | New |

| Customized | Customized |

| After-Sale Service | 1 Years |

| Shot Blasting Capacity | 100kgs/Min |

| Marketing Type | Independent Research and Development |

| Power | Customizd |

| Blasting Media | Metal Abrasive |

| Operation Mode | Working Independently |

| Maximum Size of Single Piece | <10kgs |

| Material | Small and Middle Metal or Non-Metal Parts |

| Product Name | Shot Blast Machine |

| Transport Package | Packed in Wooden Case |

| Specification | TS50/TS10/TS300/TS500 |

| Trademark | TAA Brand |

| Origin | China |

| HS Code | 8424300000 |

| Production Capacity | 1PCS/Month |

Product Description

TAA brand Rotary Drum Type Shot Blasting Cleaning Machine Wheel Blast Machine

Product Description

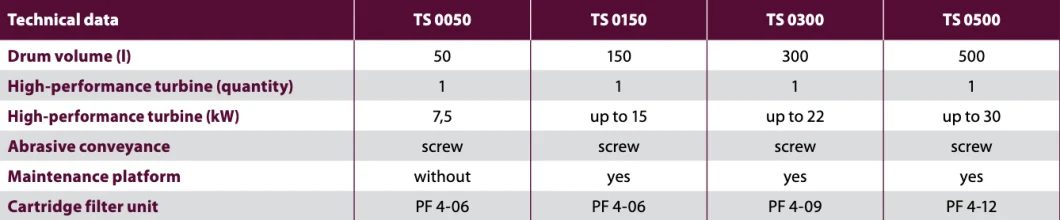

Product Parameters

Our Advantages

Advantages of drum shot blast machine

Reliable Blasting Technology

Maintenance-friendly Layout

Innovative Filter Technology

Robust Design

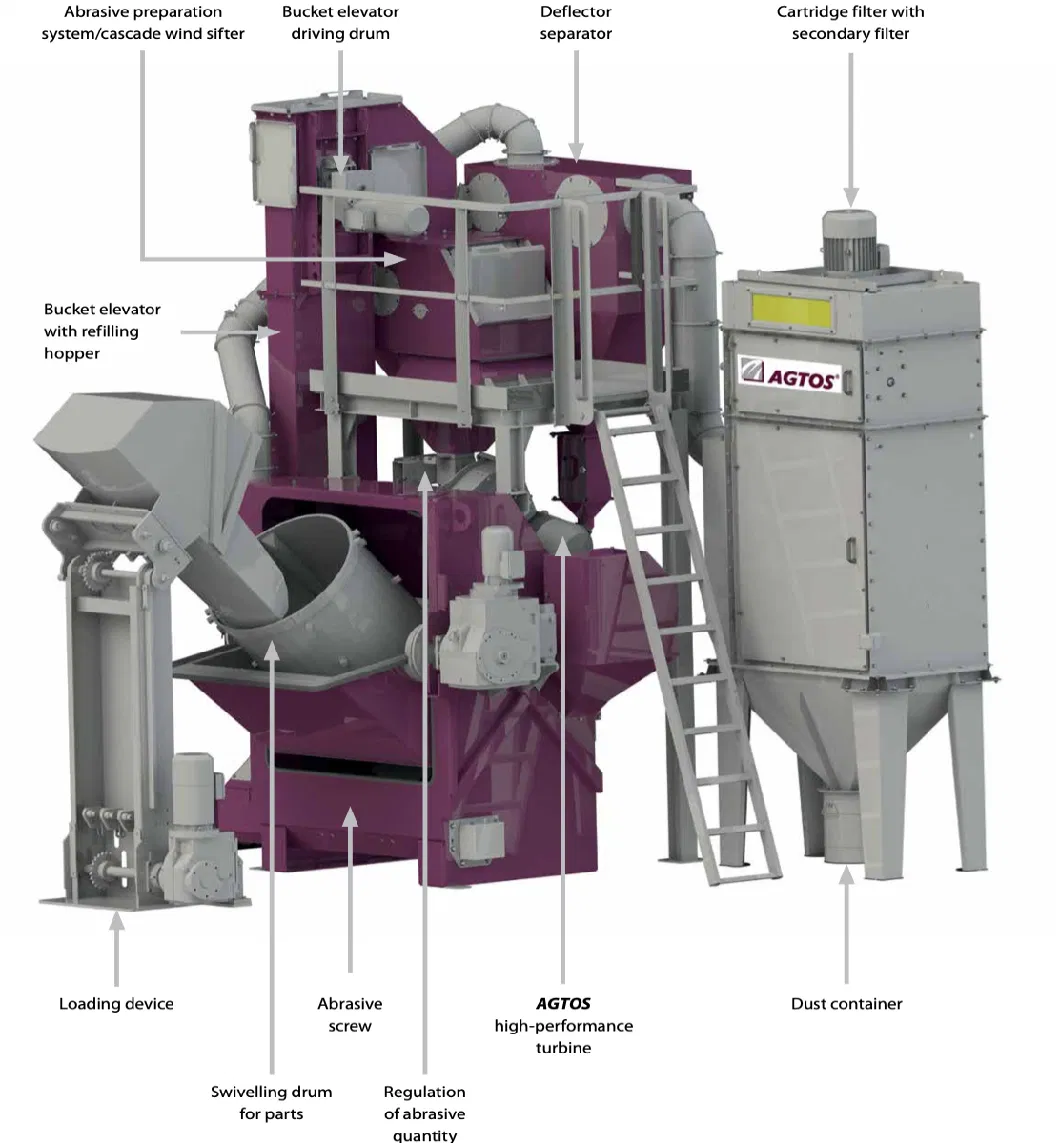

1.Blasting technology

Our high-performance turbines are solid units. Their reduced number of wear parts, maintenance-friendly design and high shot flow ensure a particularly high level of economic efficiency.

2.Maintenance-friendly layout

Regular maintenance is important for preserving the long-term value of the equipment. Large service and inspection doors provide easy access to all of the important components. As a result, wear parts can be replaced very easily.

3.Filter technology

The innovative filter system impresses with high performance. A particularly interesting characteristic feature are the conical filter cartridges which can be replaced quickly and easily outside of the machine thanks to their slide- in mechanism. These cartridge-based filter systems can be retrofitted even to older shot blast machines of nearly all other manufacturers.

4.Robust design

The sturdy design made of highly wear-resistant steel with supplementary Loading device lining of areas exposed to wear supports the operator to protect hisinvestment.

Feature

The number of wear parts has been considerably reduced (compared to steel-belt shot blast machines) thanks to the special nature of the drum.The soft swinging motion and rotation of the drum enables the gentle treatment of the parts.

The design of the drum depends on the parts to be treated.The shape and design of the bottom area and side walls ensure the optimum tumbling of the parts.

The perforation of the drum is realised in line with the specific requirements concerning the parts and the abrasive. This prevents jamming, and the abrasive can be optimally discharged.

After Sales Service

We place special value on perfect service. And not just for TAA shot blast machines but also for many other brands.

Our service program includes:

Wear and Spare Parts

Repair and (remote) maintenance

Inspection and advice

Modernisation and performance

enhancement Upgraded used machines

Instruction and Training

The TAA distribution network consists of sales agents in many countries and regional sales partners in all important industrial regions.

Company Profile

ZIBO TAA METAL TECHNOLOGY CO., LTD is the leading manufacturer of blasting abrasives in China and one of the top third suppliers all over the world. Founded in 1997, TAA has been awarded as National Hi-Tech Enterprise, owning the only metal abrasive engineering technology research center in China.

Relying on the research center,TAA has continuously developed many high-performance products more suitable for customers,including:low carbon bainite steel shot, low carbon bainite mixed abrasives, stainless steel cut wire shot, stainless steel grit etc.

Certifications

Our team

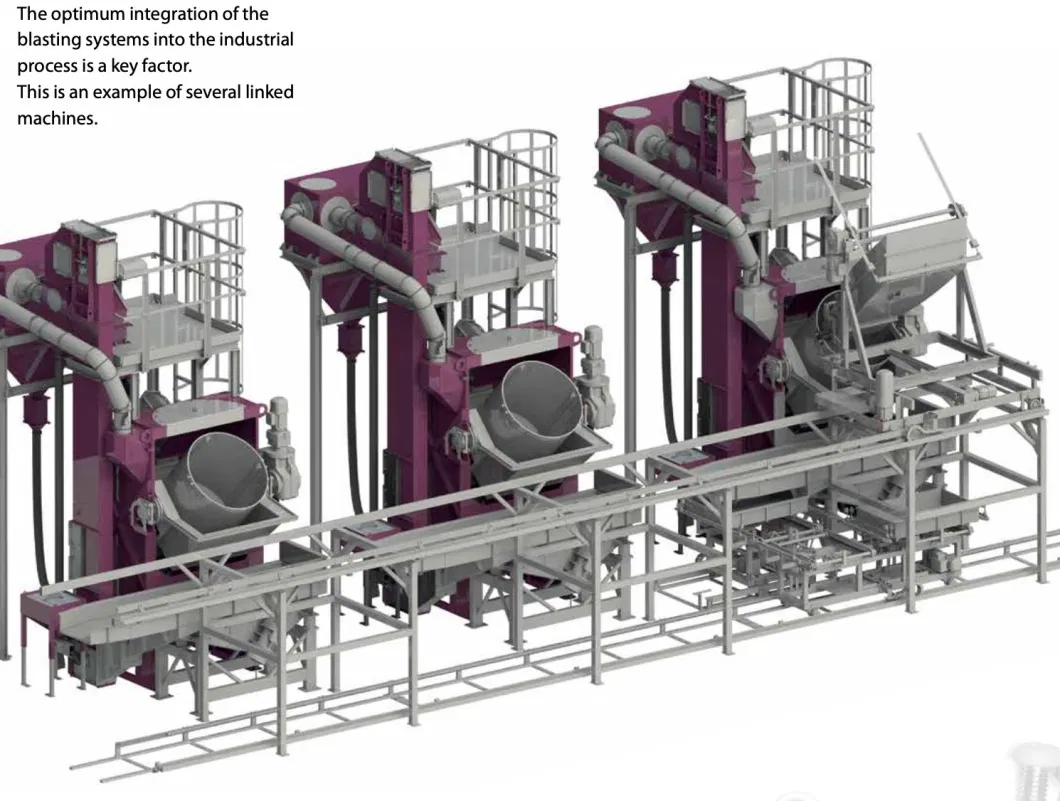

TAA committed to the provision of high-end surface treatment equipment and solutions.It has finally realized the surface treatment industry chain from metal abrasives to surface treatment equipment and overall contracting services, and as a "surface treatment integrated service provider", helping users improve production efficiency and reduce operating costs by providing high-quality products and overall services.

Our Contact